Injection Molding and Insert Molding

Injection Molding: Is used in the RF industry to produce high-precision dielectric and housing components, ensuring electrical performance and mechanical consistency. Produces precise dielectric parts with tight tolerances, critical for maintaining impedance and electrical performance.

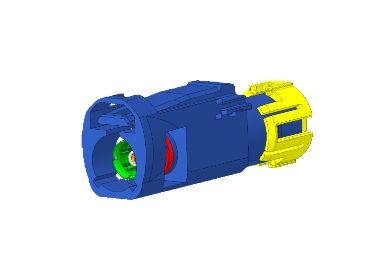

Insert Molding: Enhances this by integrating metal RF elements into molded plastic parts, creating compact, rugged and environmentally sealed interconnects. Both methods are essential for manufacturing modern RF connectors and coaxial cable assemblies at scale with repeatable, high-quality results. Combines metal and plastic in a durable, compact and sealed format, improving mechanical strength and environmental resistance.

Overmolded Camera Housing

2K (Dual Shot) LSR Molding

FAKRA Connector Housings

Injection molding is a manufacturing process where molten plastic (or sometimes rubber) is injected under pressure into a mold, cooled and ejected as a solid part. In RF interconnects, it's commonly used to create:

- Dielectric insulators inside connectors (holding center contacts in precise alignment)

- Connector shells or outer bodies (especially in low-cost or compact RF connectors)

- Cable strain relief boots and backshells

- Overmolded RF cable assemblies

Benefits in RF Applications

- High precision for maintaining critical impedance geometry

- Excellent repeatability for high-volume production

- Ability to use high-performance plastics like PTFE, PEEK or LCP that are stable at RF frequencies

Insert molding is a variation of injection molding where metal components are placed into the mold before plastic is injected. The plastic then forms around the insert, creating a single, unified part.

In RF interconnects, insert molding is used to embed:

- Metal center contacts or ground shells inside a dielectric insulator

- Shielding or EMI components within molded connector housings

- RF connectors into overmolded cable ends (forming a sealed, strain-relieved interface)

Common Insert-Molded RF Components

- SMB or MCX connectors with molded plastic insulators

- Overmolded coaxial cable assemblies for automotive or industrial RF applications

- Custom RF modules with integrated molded shields and mounting features

Why It’s Important in RF

Examples of Use:

RF cable assemblies for automotive (FAKRA, HSD) → insert-molded connectors with built-in strain reliefs

Overmolded SMA cable ends for outdoor use → injection-molded TPE or PVC boots for water resistance

5G and IoT modules → molded housings with integrated RF interfaces

Send Us a Message

Please fill in the form below and we will contact you very soon.

Fields marked with an asterisk (*) are required.