Stamping and Forming

Stamping and forming in the RF interconnect industry is used to mass-produce precise metal components like contacts and springs at high speed and low cost. These processes are essential for creating reliable, high-frequency connectors used in everything from consumer electronics to automotive and aerospace systems.

Why it matters in RF connectors?

Consistency: Stamped and formed components are highly repeatable, which is vital for maintaining impedance control and signal integrity.

Cost-efficiency: Ideal for high-volume production, reducing cost per unit.

Miniaturization: Enables creation of small, intricate parts needed in modern RF connectors such as board-to-board and automotive FAKRA systems.

Stamping is a process where flat metal sheets (typically in strip or coil form) are shaped using dies and presses to create complex parts through operations like:

- Blanking: Cutting out flat shapes from sheet metal

- Piercing: Creating holes or slots

- Bending: Pre-shaping the metal before forming

In RF interconnects, stamping is often used to make:

- Center pins (male contacts)

- Socket shells

- Grounding clips

- Contact springs or latches

These parts may be gold or silver-plated after stamping for conductivity and corrosion resistance.

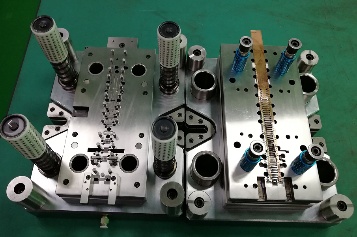

Forming follows stamping and involves bending or shaping the stamped parts into their final 3D configuration. This can be done using:

- Progressive dies (which stamp and form in multiple stages)

- Secondary forming tools (like mandrels or swaging machines)

For example:

- A flat stamped pin may be formed into a rounded, spring-loaded contact.

- A stamped clip may be bent into a U-shape to act as a ground spring in an RF connector.

Typical materials for stamping/forming in RF interconnects:

- Beryllium copper (BeCu): for spring contacts due to its excellent elasticity and conductivity

- Phosphor bronze: for moderate conductivity and good mechanical strength

- Brass: cost-effective for general contact applications

Send Us a Message

Fill out the form below and our team will get back to you promptly.

Fields marked with an asterisk (*) are required.