Tooling Development

Tooling development is essential to RF manufacturing because it defines the precision, consistency and scalability of the entire production process. Whether it's a stamping die for contacts, a mold for dielectric inserts or a crimp die for cable terminations, every tool must be engineered to support the electrical and mechanical demands of RF systems. Investing in high-quality tooling directly translates into better signal integrity, longer product life and faster, more reliable manufacturing.

What Is Tooling in RF Manufacturing?

Tooling refers to custom-designed fixtures, molds, dies and jigs used during:

- CNC machining

- Stamping and forming

- Injection and insert molding

- Crimping, assembly and testing

Each tool must be precisely engineered to match the design and electrical specifications of the RF connector or cable system.

Types of Tooling Used in RF Manufacturing

Machining Fixtures

- Hold connector bodies or contacts during CNC turning and milling

- Ensure exact positioning for features like thread dimensions, chamfers and dielectric pockets

Stamping Dies

- Used to produce center contacts, grounding tabs or spring fingers from a metal strip

- Must be capable of high-speed, high-precision operation with long tool life

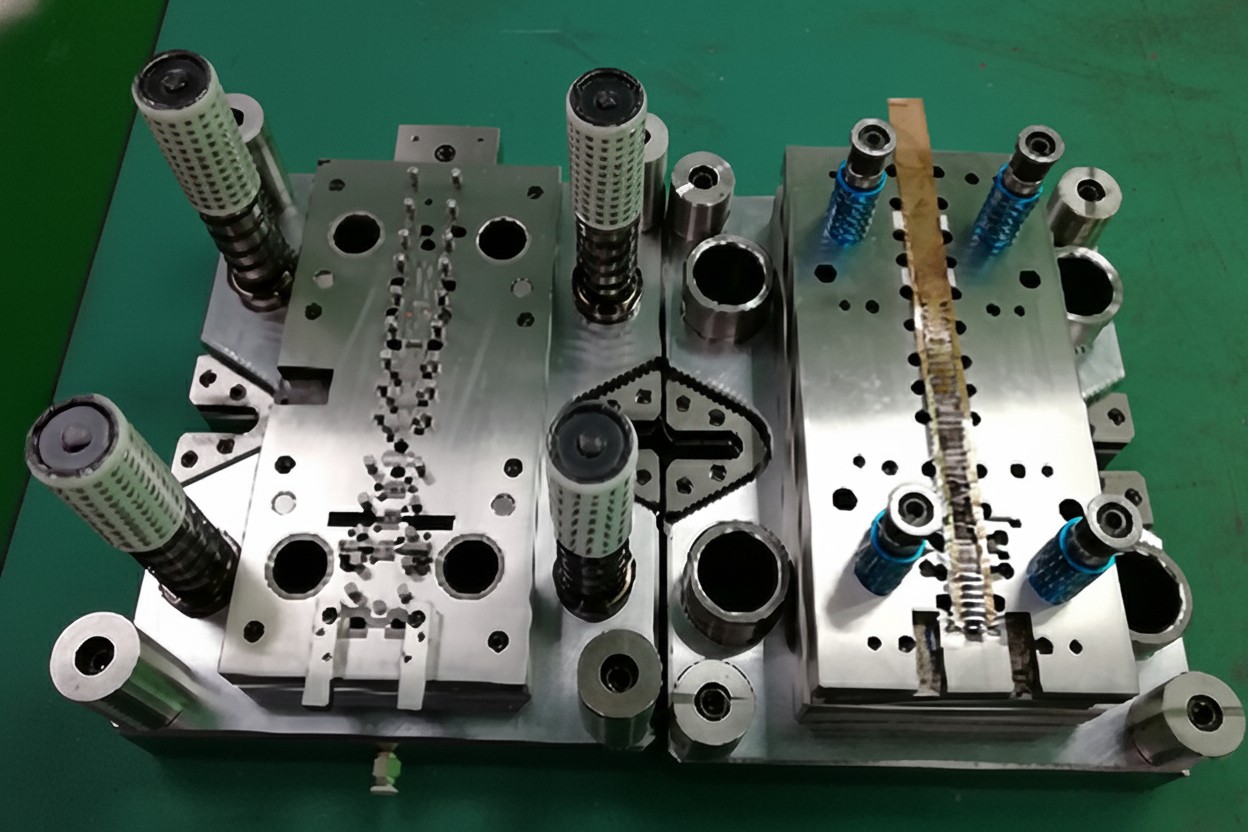

Molding Tools (Injection & Insert Molds)

- Used to form dielectric insulators or overmold RF cables

- Must maintain exact geometry for consistent dielectric spacing and impedance

Crimping & Termination Dies

- Apply specific crimp profiles to center contacts and ferrules on coax cables

- Designed for exact force and shape to maintain mechanical integrity and electrical continuity

Assembly & Inspection Fixtures

- Hold parts in alignment for soldering, gluing or automated assembly

- Often combined with vision systems or probes for inline testing

Tooling Development Process

- Design Engineering: CAD models are created based on the connector/cable geometry, electrical specs and materials

- Simulation and Prototyping: simulations (thermal, structural, RF) are used to test design performance before tool fabrication

- Tool Fabrication: high-precision machining, EDM or additive manufacturing used to create tools

- Trial Runs & Validation: early production batches are tested for fit, finish, and RF performance

- Iteration and Optimization: tools are refined to improve cycle time, reduce wear or enhance quality

Applications in Industry

- High-frequency aerospace connectors (SMPM, 2.92mm): require ultra-tight tooling tolerances.

- Automotive RF cable assemblies: use progressive stamping tools and insert molds optimized for speed and repeatability.

- 5G test cables: require precision crimp and overmold tools to ensure stable electrical characteristics across frequencies.

Send Us a Message

Please fill in the form below and we will contact you very soon.

Fields marked with an asterisk (*) are required.