Custom Camera Module Interconnect Solutions

The Amphenol RF engineering team is experienced in designing, developing, manufacturing, and testing custom module interconnects for use in Automotive and Industrial applications, as well as Aerospace, Defense, Medical, Telecommunications, Robotics and IoT systems. Our solutions support a wide range of use cases, from Advanced Driver-Assistance Systems (ADAS) and Machine vision to Smart Infrastructure, autonomous platforms and next-generation connectivity.

Why Engineering Teams Choose Amphenol RF

- Reduce integration risk with camera interconnect architectures proven in automotive platforms

- Optimize packaging with internal and external connector strategies tailored to your module design

- Maintain supply continuity through vertically integrated manufacturing

- Accelerate validation with rapid tooling and early performance testing

- Enter production with confidence, backed by full mechanical, electrical and RF qualification

.png)

- Engineering Value That Accelerates Your Camera Module Design

Designing a custom camera module requires tight coordination between RF performance, mechanical packaging, environmental protection and manufacturability. Amphenol RF brings these disciplines together to help teams move from concept to production faster, with fewer iterations and less risk.

Protocols and Architecture Supported by our High-speed Coaxial SolutionsToday’s camera systems demand high bandwidth, low latency, and EMC robustness over extended distances. Amphenol RF supports leading automotive camera protocols with interconnects engineered for controlled impedance, shielding performance, and mechanical reliability.

SerDes Camera Links

Designed for the automotive industry, SerDes camera enables high-bandwidth long-distance transmission up to 25 meters.

- GMSL

GMSL™ is a high-speed serial interface designed for low latency and long-distance transmission. It operates over coaxial cables with FAKRA connectors.

-

Point-to-point interface unlike USB or Ethernet

- Up to 12-16 Gbps

-

Single coax or STP cable

-

Power + data + control over one cable

-

Supports high frame rate data capture even under vibration, temperature shifts and EMI-prone conditions

-

Widely used in ADAS, surround view and front cameras

-

Ideal for harsh mobility environments such as construction equipment, automation farm vehicles and mining robots

-

- FPD-Link

FPD-Link™ is a serial interface developed for automotive imaging applications. It supports high-speed video transmission over a single coaxial cable.

-

Up to 16 Gbps

-

Single coax or STP cable

-

Supports refined image delivery up to 15 meters in real-time

-

Widely used in ADAS and front cameras

-

Ideal for distributed camera systems in vehicles and robots

-

MIPI

MIPI™ is a high-speed, low-power interface used to connect cameras, displays and sensors to processors. The first-generation MIPI™ interface was critical in laying the groundwork for camera interfaces in early camera-enabled devices.

- MIPI A-PHY

- Automotive grade long-reach MIPI™

- Operates over coax or STP cable

- Up to 16-32 Gbps

- Can be used with FAKRA/Mini-FAKRA connectors

- Designed for harsh EMI environments

Design Considerations for Custom Interconnects

Amphenol RF designs its camera module solutions around a set of key considerations that ensure reliable performance across a wide range of applications.

Key design considerations include:

|

External Interconnect Selection FAKRA or Mini-FAKRA, based on system performance and packaging requirements |

Internal Interconnect Approaches SPC, UD-AFI, direct soldering or multi-piece configurations based on mechanical and electrical needs |

Pig-tail Options Flexible design choices to accommodate camera module architecture |

|

Housing Materials Aluminum, plastic or metallized plastic |

Cleanliness Requirements Critical for maintaining long-term electrical performance and reliability |

Ruggedization and Sealing Designed to withstand harsh automotive and industrial environments |

|

Application Diversity Side mirror, driver monitoring and front, rear and surround view systems, each with unique environmental and performance demands |

Value-driven Solution Economically efficient design aligned to camera design and performance requirements |

Interface Performance Drivers Mating force, retention, contact resistance and package size guide geometry |

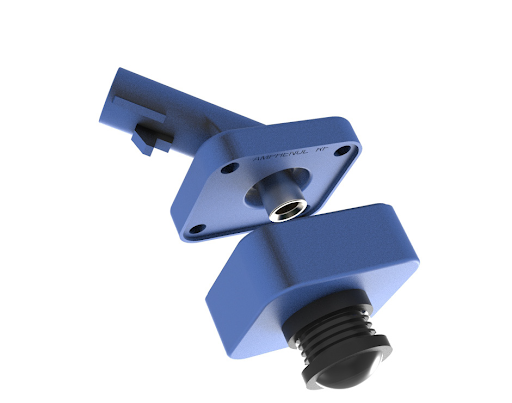

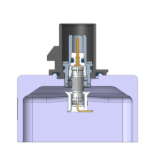

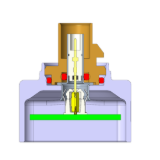

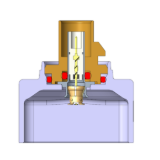

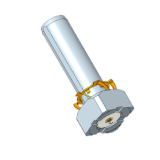

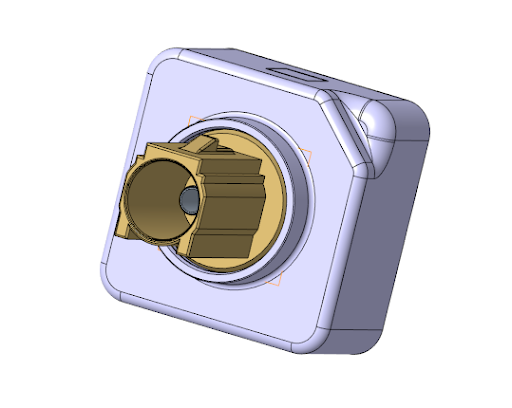

Internal Interconnect Solutions for Diverse Requirements

Camera modules in automotive, industrial and infrastructure applications require reliable high-speed transmission, precise mechanical alignment and consistent performance in space-constrained environments.

Our internal interconnect designs can be tailored to manage:

Mating force targets

Axial and radial float

Side-load tolerance

Packaging constraints and alignment needs

3-Piece Floating

| 2-Piece Floating

| 2-Piece Low Float

| 2-Piece Limited Float

| 1-Piece No Float

|

|  |  |  |  |

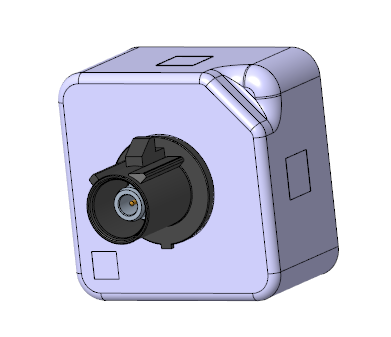

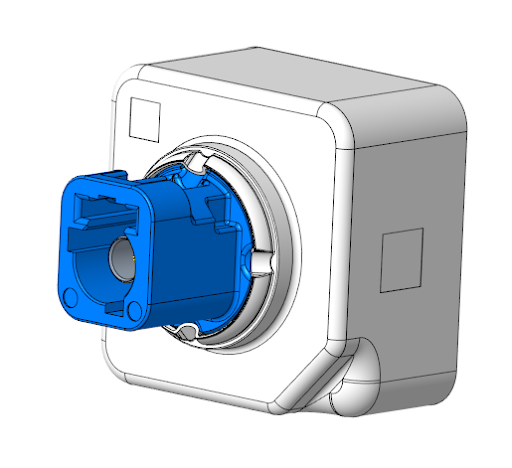

External Connector Interfaces

Amphenol RF offers multiple external connector interface options to support different performance, packaging and cost requirements in automotive and industrial camera systems.

FAKRA – Well-understood ecosystem, but higher vibration sensitivity

Mini-FAKRA – Better EMC control and higher frequency performance, with cable constraints

Pigtail – Lowest cost and smallest footprint, but trades off serviceability

|

|

| Pigtail (Direct Cable)

|

|  |  |  |

Housing Materials for Camera Backs

Housing selection is an RF and mechanical decision, not just a structural one. Material choices impact shielding, grounding strategy, thermal behavior and long-term dimensional stability.

| Option (with materials) | When it’s usually a good fit | Key Benefit | Trade-off |

| Reinforced plastics (PA66 GF, PBT GF) | Most high-volume camera housings | Lightweight, strong, cost-effective | Typically needs an added EMI strategy |

| High-temp plastics (PPS GF, LCP) | High-temperature locations, tighter tolerance/alignment needs | Better shape stability over heat and time | Higher material cost |

| All-metal housings (Die-cast aluminum, aluminum extrusion, stainless steel) | Maximum EMI shielding + rugged exterior designs | Built-in shielding + robust structure | Higher weight and usually higher cost |

| Plastic + metal insert/plate (PA66 GF or PBT GF + stamped stainless/steel insert, aluminum insert) | Best balance of weight + shielding | Stronger, more predictable grounding than plastic alone | Added assembly complexity |

| Shielded plastic (PA66 GF, PBT GF, PPS + conductive coating) | When you want lighter weight but need moderate shielding | Adds shielding without full metal | Coating durability must match the environment |

Cleanliness Requirements

As camera systems become critical to safety, automation and data accuracy, cleanliness during manufacturing plays a direct role in long-term performance and reliability. At Amphenol RF, our custom camera modules are produced under strict cleanliness and contamination-control standards to ensure consistent signal integrity, optical clarity and dependable operation in demanding environments.

The clean room operates under negative pressure to further control airborne particulates. Particle levels are continuously monitored to meet ISO Class 7 requirements, which allow a maximum of 2,930 particles per cubic meter greater than 5 microns and fewer than 352,000 particles per cubic meter greater than 0.3 microns. The facility also maintains a minimum of 60 air changes per hour to ensure consistent air quality.

The facility manages cleanliness standards such as VDA 19.1, commonly used in Europe, and ISO 16232, widely used in North America, and can accommodate custom cleanliness specifications as required.

Controlled Manufacturing Environments

Our manufacturing controls support:

Reduced particulate levels to protect lenses, sensors and connectors

Controlled humidity to prevent moisture absorption and corrosion

Strict material handling procedures to avoid residue transfer and surface contamination

These practices help ensure every camera module meets precise performance and reliability expectations before leaving our facility.

.png)

Clean Assembly for Optical and RF Integrity

Cleanliness directly impacts both image quality and RF signal performance. Contaminants can introduce optical distortion, reduce sensor sensitivity and increase RF insertion loss or impedance instability. Amphenol RF’s cleanliness requirements help preserve:

Optical clarity and consistent image quality

Stable RF transmission between camera modules and system electronics

Long-term reliability in sealed or ruggedized system designs

Each assembly step follows defined cleanliness protocols to protect critical contact interfaces and optical surfaces.

Ruggedization and Sealing

Modern RF systems operate far beyond clean, controlled environments. From vehicles and factories to outdoor infrastructure and mission-critical platforms, connectors must withstand vibration, moisture, temperature extremes and contaminants. Amphenol RF engineers its connectors to perform reliably in these demanding conditions through advanced ruggedization and sealing technologies.

Built for Mechanical Durability

Our ruggedized designs maintain electrical integrity under continuous physical stress, withstanding vibration, shock, high mating cycles, mechanical strain, and wide temperature ranges without compromising RF performance. Robust coupling mechanisms, reinforced contacts, and high-strength connector bodies help prevent loosening, deformation and signal degradation over the life of the product.

Advanced Environmental Sealing

To protect critical RF interfaces, Amphenol RF integrates proven sealing technologies such as O-rings, panel seals, and IP-rated options including IP67 and IP68. Corrosion-resistant materials and platings ensure long-term durability in outdoor, high-humidity, and chemically aggressive environments, while environmental and hermetic sealing solutions support extreme and mission-critical applications. These features help maintain consistent performance by preventing moisture absorption, dielectric contamination and corrosion.

Performance You Can Rely On

Together, ruggedization and sealing deliver stable impedance, low VSWR, and consistent insertion loss over time, resulting in long-term reliability, reduced maintenance and minimized downtime.

From ADAS and electric vehicles to industrial automation, wireless infrastructure, and defense systems, Amphenol RF connectors are designed to protect both your signal and your system investment. When performance matters most, trust Amphenol RF to keep your connections secure, sealed and reliable.

Talk to an Amphenol RF Camera Interconnect Engineer

Engage our engineering team to define a camera back and interconnect solution optimized for your performance, packaging, and environmental requirements.

next design.