Modifications of Existing Products

Special Plating or Finishes

Signal integrity often begins at the surface. Whether you need low‑intermodulation nickel‑phosphorus, corrosion‑resistant black zinc‑nickel, RoHS‑compliant gold flash or any other specialty coating, our design engineers specify the optimal thickness, surface roughness and under‑plating structure to hit both electrical and environmental targets without over‑engineering cost into the design.

Material Modifications

From stainless steel for salt‑spray environments to high‑temperature LCP insulators that survive automated reflow, we routinely swap in alternative metals and plastic components. Material changes are validated for conductivity, tensile strength, flammability rating and long‑term aging so you can certify the finished assembly with confidence.

RF Performance Enhancements

Need lower VSWR at 18 GHz, tighter phase matching, or extended high-frequency operation? Our RF specialists re‑optimize pin geometry, dielectric interfaces, and ground paths, then verify the results with full‑wave 3‑D EM simulation and network‑analyzer data. Fine‑tuned performance means cleaner signals, higher data rates, and wider design margins.

External Geometry Modifications

Space is always at a premium. We tailor connector height, footprint, and mating interfaces to drop into crowded board outlines, stacked mezzanines, or blind‑mate rack systems—while maintaining all published mechanical and electrical specs. Custom keys, positive latching, and color‑coded housings further streamline your assembly process.

Ruggedization

Harsh environments demand more than standard catalog parts. We convert multi‑piece bodies into seamless single‑piece constructions for higher shock and vibration resilience, add integrated O‑ring or gasket features to achieve IP67+ sealing, and qualify to MIL‑STD‑202 environmental standards as required. The result: mission‑critical reliability from farm machinery to battlefield radios.

Value Engineering

When volumes rise, we pivot from prototype to production economics. Our team reviews plating stack‑ups, raw‑material utilization, and secondary operations to drive out unnecessary cost without sacrificing performance. The result is a connector that meets your technical needs and your business case from a cost perspective.

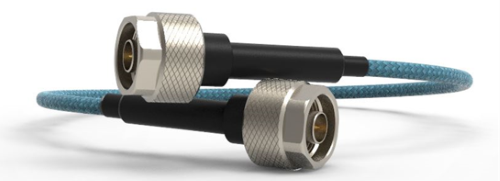

RF Interconnects

A Collaborative Development Process

Scoping the Design

Your sales engineer and our applications team turn your performance requirements, environmental conditions and cost targets into a detailed technical statement of work.

Concept Development

We generate 3‑D models and preliminary simulation data so you can see how the connector integrates mechanically and electrically before any metal is cut.

Simulation & Analysis

Using industry‑standard EM tools, we optimize impedance, insertion loss and crosstalk, then share s‑parameter files for system‑level modeling.

Rapid Prototyping

In‑house CNC machining and additive manufacturing provide first articles in weeks, often accompanied by full RF test reports.

Qualification & Pilot Production

Environmental, mechanical and RF validation proceeds in Amphenol RF’s certified labs, followed by pilot runs on the same equipment used for full‑scale manufacturing.

Full‑Scale Manufacturing

Global, vertically integrated factories deliver volume with consistent quality, backed by Amphenol’s comprehensive supply‑chain, quality and traceability systems.Ready to Build Your Perfect Connector?

Bring us your toughest size, weight, power or performance challenge, and Amphenol RF will transform a standard connector into a custom‑engineered solution that accelerates your time‑to‑market.

next design.

Send Us a Message

Please fill in the form below and we will contact you very soon.

Fields marked with an asterisk (*) are required.