SSMA Connectors

High-frequency, compact RF connectors designed for demanding precision applications

Overview

Amphenol RF’s SSMA connectors are compact, subminiature solutions developed to meet the growing demand for higher frequency, precision RF performance in space-constrained applications. These 50 ohm connectors are ideal for use in systems where SMA connectors are too large, offering similar mechanical designs in a smaller form factor.

Engineered for DC to 40 GHz performance, SSMA connectors feature a screw-on coupling mechanism that ensures consistent electrical performance and mechanical stability even in challenging environments. Their robust design makes them suitable for test and measurement, instrumentation, military and aerospace systems.

Features and Benefits

- Operates up to 40 GHz for high-frequency performance

- Compact design ideal for limited-space installations

- Threaded coupling mechanism ensures secure mating

- High-quality stainless steel construction for durability

- Compatible with a wide range of precision coaxial cables

Key Technical Details

- 50 ohm impedance

- Broadband performance up to 40 GHz (cable dependent)

- Screw-on coupling ensures reliable mechanical connection

- Compatible with precision RF systems in commercial and military sectors

Applications

- Test and measurement equipment

- Military communications systems

- Aerospace and defense platforms

- Instrumentation and sensor interfaces

- High-frequency signal transmission in compact environments

Browse our full line of SSMA connectors to find a solution that fits your design requirements. If your application calls for a custom configuration, our team is available to support your engineering needs.

Specifications

SSMA Connectors

Electrical

| Impedance | 50 Ohm |

| Frequency Range | DC - 34 GHz |

| Voltage Rating | 250 Volts RMS Continuous |

| Dielectric Withstanding Voltage | 750 VRMS Max |

| VSWR (Return Loss) |

|

|

DC - 18 GHz

|

1.10 + .005*f (GHz) Max |

Environmental

| Temperature Range | −65°C to +165°C |

| Thermal Shock | MIL-STD-202, Method 107 (Test Condition B) except high temp test @ +200°C |

| Corrosion | MIL-STD-202, Method 101 (Test Condition B) - 5% Salt Solution |

| Vibration | MIL-STD-202, Method 204 (Test Condition D) |

| Mechanical Shock | MIL-STD-202, Method 213 (Test Condition B) - No Discontinuity Permitted |

| Moisture Resistance | MIL-STD-202 Method 106 |

Mechanical

| Mating Cycles | 500 Min |

| Coupling Mechanism | Threaded |

| Interface Specification | MIL-STD-348 |

| Mating Torque, Min Working | 0.45 N-m (4 in-lbs) |

Note: These characteristics are typical and may not apply to all connectors.

Connector configurations may affect performance.

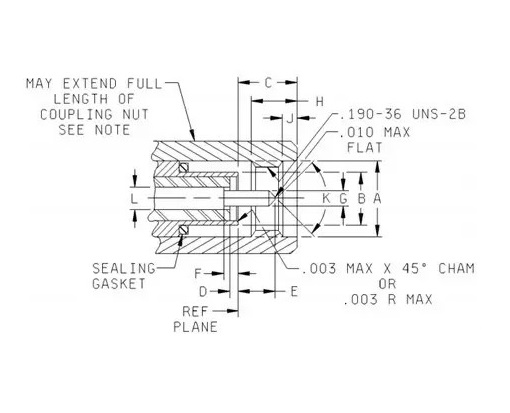

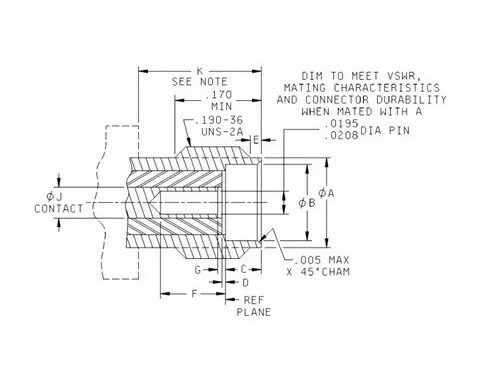

Interface Dimensions

Plug

Jack

Send us a Message

Please fill in the form below and we will contact you very soon.

Fields marked with an asterisk (*) are required.