Low-PIM

Amphenol RF’s low-PIM connectors minimize unwanted interference for superior performance. By reducing passive intermodulation at the source, these solutions ensure reliable, high-quality connectivity across wireless networks and critical communication infrastructure.

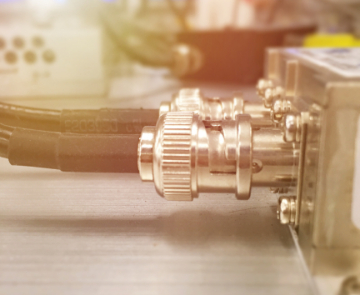

Low-PIM RF connectors are specifically designed to protect against signal degradation in applications where multiple frequencies operate simultaneously. Constructed from premium non-ferrous materials with precision tolerances and optimized plating, they reduce the creation of unwanted intermodulation products that compromise system integrity. Their robust design ensures stable electrical performance under vibration, temperature fluctuations and mechanical stress, making them an essential choice for cellular networks, satellite links, radar installations and broadcast systems. By maintaining signal purity, these connectors help extend system life, reduce costly downtime and support the ever-increasing demands of modern communication technology.

Amphenol RF’s extensive portfolio of low-PIM solutions includes connector series such as 2.2-5, 4.3-10, 4.1-9.5, 7-16 and N-Type, each optimized for specific performance and footprint requirements. These connectors support frequencies up to 11 GHz, ensuring flexibility across telecommunications, distributed antenna systems (DAS) and high-data-rate wireless infrastructure. Their proven reliability also makes them indispensable in specialized applications such as medical imaging equipment and test and measurement systems, where accuracy and signal stability are non-negotiable. Across industries, Amphenol RF low-PIM connectors deliver the consistency, durability and electrical performance required for high-integrity RF communication.

Send us a Message

Please fill in the form below and we will contact you very soon.

Fields marked with an asterisk (*) are required.