Industrial

.jpg)

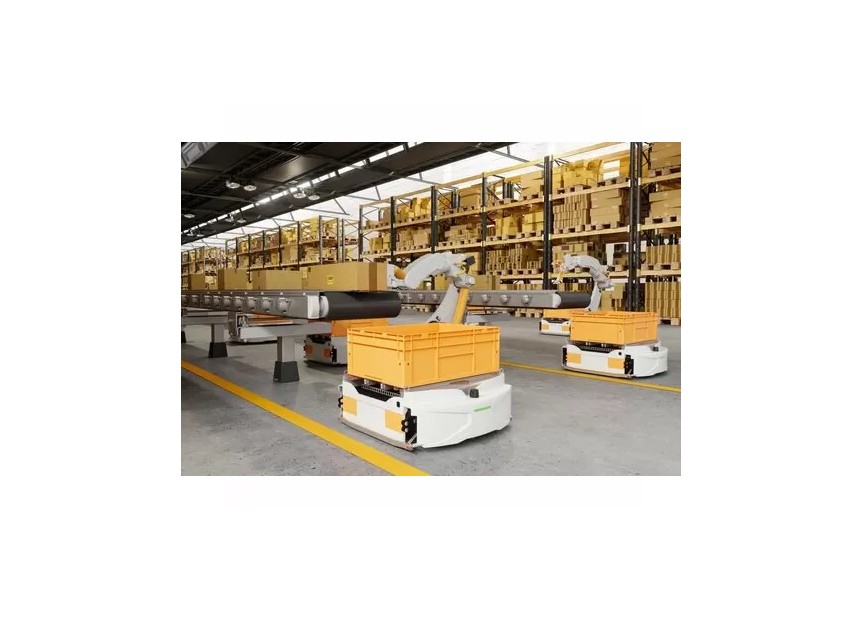

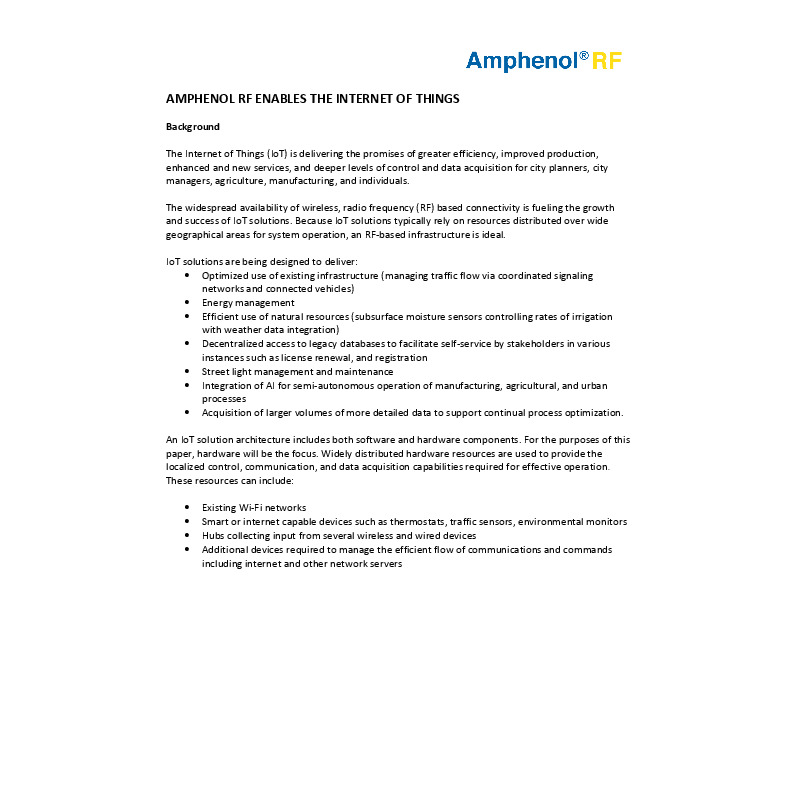

The industrial market encompasses a vast range of sectors, including manufacturing, construction, energy and transportation, all of which are fundamental to global economic growth. This market demands highly specialized products, equipment and technologies that can withstand harsh environments, provide reliable performance and drive productivity. With a focus on efficiency, durability and scalability, companies within the industrial market are paving the way for next-generation infrastructure and processes that shape modern industry.

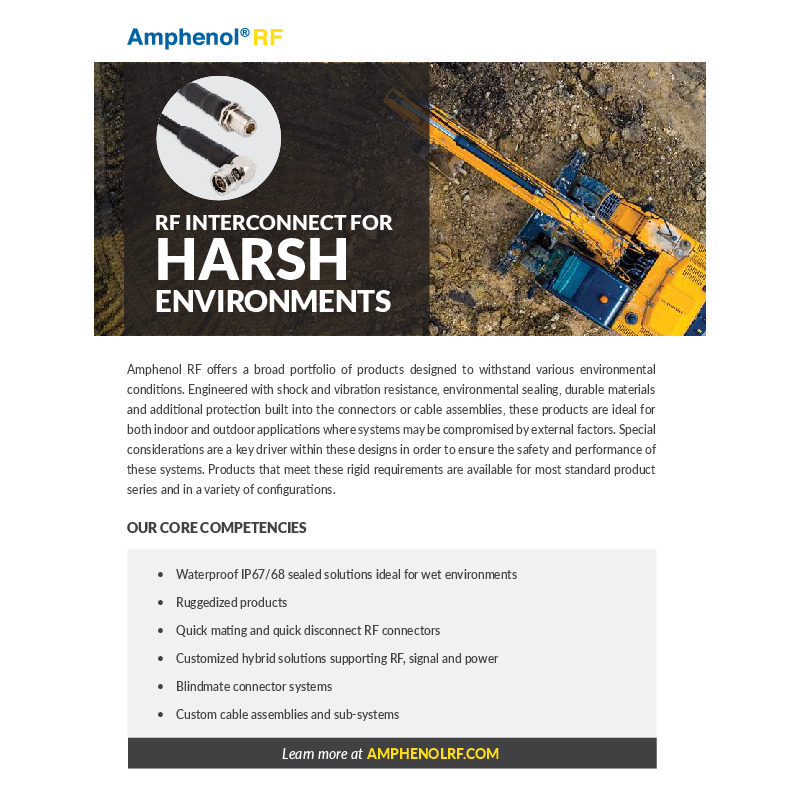

Industrial operations depend on robust, long-lasting connectivity that can handle harsh conditions and nonstop demands. Whether it’s a sensor network on an automated assembly line, a control system in a remote mining site or heavy equipment exposed to vibration, dust and moisture,

every connection must deliver reliable power and data transfer day after day. Our extensive portfolio of RF connectors, sealed cable assemblies and custom solutions is built for these challenges, providing the durability and signal integrity that keep operations running smoothly.

Industrial Grade RF Performance for Next Generation Industrial Ecosystems

As factories become smarter and more connected, the need for secure, high-speed communication grows. Our products enable machine-to-machine communication, real-time monitoring and predictive maintenance, helping businesses reduce downtime and boost efficiency. Designed for easy integration and minimal maintenance, our

solutions support industrial IoT, robotics, process control and other technology within the industrial ecosystem, ensuring that vital systems stay online, no matter the conditions. Modern production demands maximum uptime and zero signal failure. Our industrial-grade interconnects are engineered to perform in extreme temperatures,

high-vibration zones and corrosive environments, giving manufacturers the confidence that their equipment will operate reliably shift after shift. Rugged sealing and robust locking mechanisms protect sensitive connections from dust, oil and water, extending service life and minimizing unplanned repairs.

Industrial Applications

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

Related Resources

Industry Trends

Send us a Message

Please fill in the form below and we will contact you very soon.

Fields marked with an asterisk (*) are required.